MES

Manufacturing Execution System

Coordinating Man, Machine, Material, Method, and Environment to build a transparent, real-time, efficient digital platform.

Defining Next-Gen

Digital Transparent Factory

Guanling Tech self-developed MES integrates shop-floor data with business execution, enabling quality improvement, efficiency gains and lean inventory.

Data Integration

Connect PLC, SCADA and equipment seamlessly, eliminating silos.

Business Decomposition

Translate ERP plans into actionable shop-floor tasks for closed-loop control.

17+ Core Modules

Cover the full lifecycle from order to finished goods with data-driven operations.

1

Workshop Modeling

2

Production Planning & Scheduling

3

JIT Sync

4

Production Task Gantt Chart

5

Process Modeling

6

Process Constraints

7

Tag Management

8

4M Error-Proofing Mechanism

9

Smart Operation

10

Program Mgmt

11

Traceability Management

12

WIP Mgmt

13

Progress Tracking

14

Labor Value

15

Smart Flow

16

AGV Monitor

17

Visual Board

18

MORE

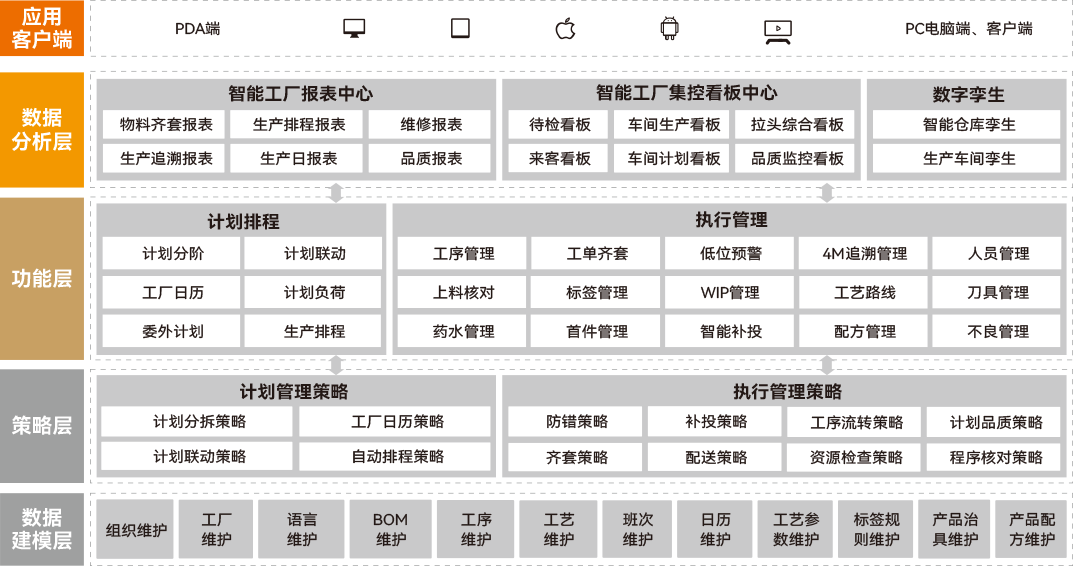

System Architecture

Core Advantages & Value

Smart Flexible Scheduling System

Real-time Gantt charts visualize planning and completion progress

Flexible Workshop Process Modeling

Optimize process configuration to adapt to changing demands

4M Multi-level Error Proofing

Comprehensive recording and control of process variations

Standard/Custom Report Dashboard

Real-time factory data for transparent management

Smart Changeover JIT Supply

Low-stock alerts, smart changeover for lean production

Ready to Start?

Contact Us

Whether it's RFQ or a digital consultation, our experts respond within 24 hours.